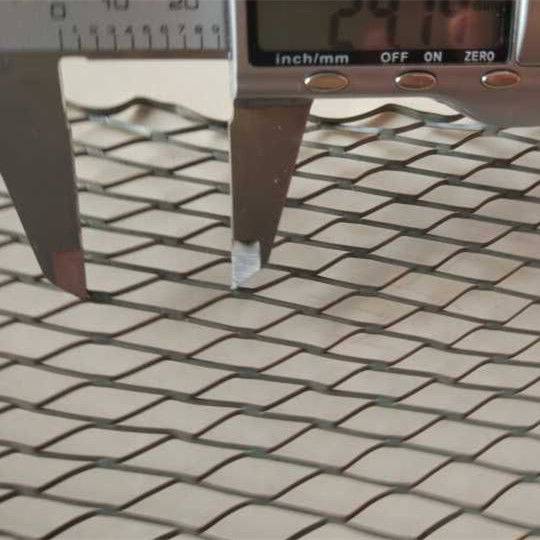

Iimbambo eziphakamileyo zenziwe ngetsimbi eyandisiweyo yentsimbi

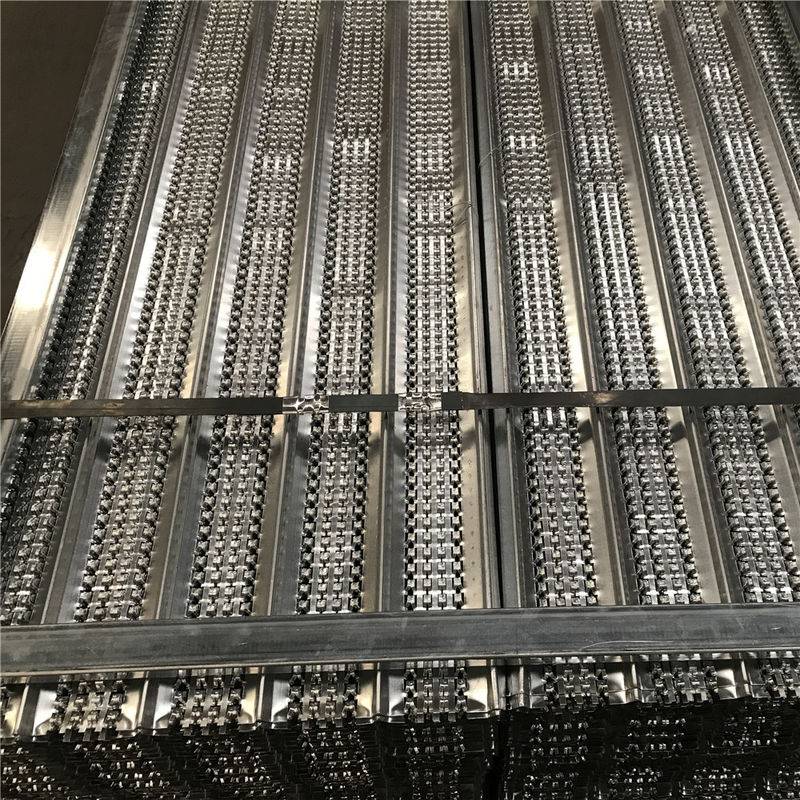

| Izinto: | Isefu yentsimbi kwalenza | Hole Imilo: | Idayimani |

|---|---|---|---|

| Phawu: | Yomelele kwaye iQinisekile, Inkangeleko entle | Isicelo: | Ulwakhiwo loMgangatho, iNdlela |

| Ukukhanya okuphezulu: |

Isefu eyandisiweyo yentsimbi, isicaba sentsimbi esandisiweyo |

||

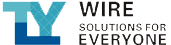

Ubambo obuPhakamileyo beNsimbi eyandisiweyo esetyenziselwa ifomu yokwakha

Iimbambo eziPhakamileyo ze-Metal Lath Amaxabiso anokusetyenziselwa ukwenza udonga, umqadi kunye nomphezulu wekholamu kunye ne-slab soffits. Ubambo oluphezulu lwensimbi eyandisiweyo lath luhlobo lwemveliso eyandisiweyo yentsimbi eshinyeneyo esetyenziswa kwifom esisigxina yekhonkrithi. Ubunjineli obuchanekileyo obuvulekileyo bocingo lweMesh lwenza ukuba kuphuculwe izixazululo zekhonkrithi ezixineneyo ebusweni beembambo, ukudala isitshixo esiphezulu senqanaba lesibini. Isetyenziswe ikakhulu kwizicelo zokudibanisa kunye neziphelo zokumisa. Isefu ezinamacala wocingo, wocingo, Isefu welding wocingo, welding iPhaneli Wire.

Ukusetyenziswa

Njengomsebenzi osisigxina wekhonkrithi ongenasiseko somsebenzi, esetyenziswa ngokubanzi kwiibhulorho zeetonela, iinkqubo zangaphantsi zevalve, iinkqubo zogutyulo, iindlela zangaphantsi, ukugcina iindonga, izityalo zamandla enyukliya, iivenkile zeenqanawa, Amachibi oManzi obunjineli baselwandle asebenza ngeeprojekthi zokwakha eziphakamileyo, iphethini engaqhelekanga okanye yokugoba njl. .

Ukupakisha:Ngu-Iron Pallet. Iifayile ezili-10 / inyanda, iinyanda ezingama-50 / pallet.

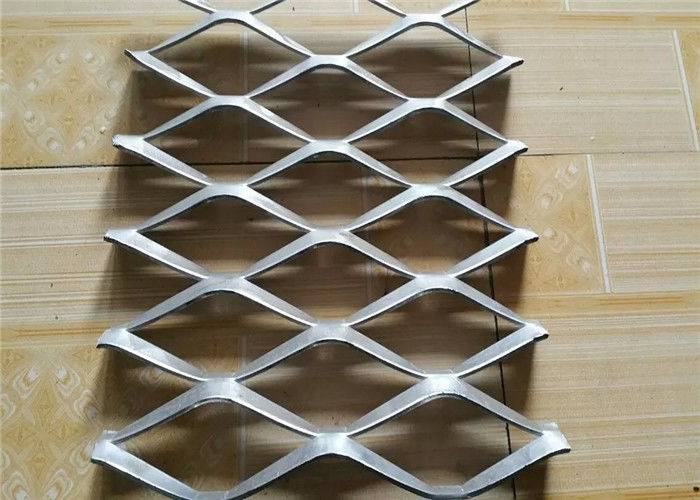

| Izinto eziphathekayo | Ukutyeba | Ukuphakama kwembambo | Umgama weRib | Ububanzi | Ubude |

| Zinc Plate | 0.45mm | 20mm | 89mm | Ubukhulu: 445mm | 2200mm |

| Isefu | 0.50mm | 21mm | 89mm | Ubukhulu: 445mm | 2000mm |

| Ipleyiti yentsimbi | 0.35mm | 19mm | 89mm | Ubukhulu: 445mm | 2500mm |

| Yenziwe ngentsimbi eshayinayo | 0.4mm | 12mm | 89mm | Ubukhulu: 445mm | 3000mm |

UMthengi wethu

FAQ

1. Ngaba unokubonelela ngesampulu yasimahla?

Ewe sinokubonelela ngesampulu yasimahla kwisiqwenga esincinci kunye nekhathalogu yethu. Kodwa intlawulo yekhuriya iya kuhlawulwa kwicala lakho. Siya kuthumela kwakhona ikhuriya xa ubeka iodolo.

2. Lithini ixesha lokuhlawula?

Ngokubanzi, ixesha lethu lokuhlawula li-T / T 30% kwangaphambili, i-70% xa kuthelekiswa nekopi ye-B / L. Amanye amagama okuhlawula anokuxoxwa ngawo.

3. linjani ixesha lokuhambisa kwakho?

Ngokwesiqhelo ngokwezinto zakho, ixesha lokuhanjiswa kwibhotile enye yeenyawo ezingama-20` ziintsuku ezingama-25. Sinokuhlengahlengisa ixesha lokuvelisa kwi-oda yakho engxamisekileyo.

4. Ngaba uyazi intlawulo yokuthumela kwizibuko lelizwe lam?

Ewe. Sinearhente yethu ejongene nemicimbi yokuhambisa. Siza kukunika eyona nqanawa kunye nentlawulo.

5. Hot shushu kwalenza phambi welding kunye shushu nkxu kwalenza emva welding, yeyiphi engcono?

Ngokucacileyo kushushu nkxu kwalenza emva kwentsimbi, kuba kuya kubakho i-zinc kwindawo ye-welding eyenza ukuba kungabikho lula ukufumana umhlwa. Kuya kubakho indawo iwelding kwi eshushu nkxu kwalenza phambi welding.